|

During the summer of 2003, Gene Funderburk (Guru in Residence and Theatrical Physicist) and Rhett Bryson have been working on making MANY improvements to the scenic construction shop. These improvements are in service of increased SAFETY, efficiency, productivity and appearance. As additional changes and additions are made, pictures will be added to this page. |

The

NEW Dust Sucker machine!

(After YEARS of

waiting, the scene shop finally has the fabulous dust sucker machine

installed - check out the details of the

installation.)

|

Most of these improvements are the result of the clever, inventive, imaginative and craftsmanlike skill of GuruGene. He has engineered and fabricated many of these items out of material found in the shop or economically obtained locally, saving hundreds if not thousands of dollars over what commercially available products would have cost the theatre. Every theatre probably needs a GuruGene - but they can't have him, he is OUR guru! (Special GuruGene graphic by Denise Bryson) |

Massive improvements to the table saw! Completely new side table, new rip fence SYSTEM, blade guard, outfeed table PLUS folddown outfeed table extension, switch relocation and easy off bump bar, rolling undertable cabinet with pull out blade drawer, drawers and storage for new crosscut sled. There are many T track accessories - hold downs, featherboards, stops, etc.

NEW drill press table system. T tracks in the top and side tables and on the fence. Hold downs and stops, etc for the T tracks. new rolling table with drawers for accessories.

New trash bin for cutoffs and other debris on wheels under the radial arm saw. New fence with T track for accessories, stops, etc. New masonite table top.

One of two retractable wall mounted air hose stations. (The other one is over by the table saw installed in the outlet behind the rolling scaffold.

Rolling shop work center. Two plugging strips, drawers on both sides, storage for al of the mini tools, adjustable light attached, clamps, vices, fold down work table surface.

NEW rolling table for the chop saw. Custom design (Gene's!) extension arms, folding extension arms, drawers and under table storage. T tracks on the fence for stops and accessories.

NEW Espresso Center. Perfect height for monitoring the brewing, storage for espresso bricks and shelf for the knock box. Drawer for cups and accessories. Custom holder for sugar and coffee can with spoon holder. Note the wonderful "Espresso Machine Cozy" that Kathleen made. It is in a very tasteful espresso color scheme and is made from Irish linen with professional piping. No more dust in the espresso!

The "Museum of the

CutAwl"

L to R : K-7, K8, K9, K10 CutAwls to join the K11 that the theatre

already owned. A custom case will eventually be constructed for these

historic machines.

Router Table

Spiffy NEW Professional Router Lifter (one revolution of the crank

raises the router 1/16th of an inch!) Router bits can be easily

changed from the table top. The completely adjustable router fence

has multiple T Tracks. There are safety guards and starter pins on

the table top and fence. There is also a miter track in the front of

the table top.The multiple drawers and cabinets hold adjustment

tools, accessories, bits and other items associated with the routing

activities. The whole cabinet is on wheels to allow the routing to

take place anywhere in the shop. Note especially the unique window

into the router compartment. gene has added a light to the

interior of the router compartment which turns on when the router is

switched on. Multiple connections to the sawdust collection system

will be made to the fence and the router compartment.

Assembly Table Improvements: Top resurfaced with masonite and

poplar edging, vice moved from "CutAwl Table", Undertable storage

shelf added. (MORE improvements to this table in the works)

New storage for roll paper, addition of second roll for white

paper (to be added, roll of waxed paper.)

Radial Arm Saw improvements: New transparent blade guard,

Additions of hose for connection to the dust collection system to

come, clever dust trapping box behind the saw (GuruGene

engineered)

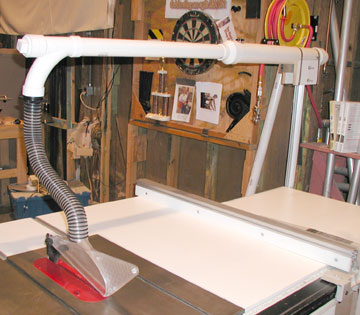

Table Saw improvements: New blade guard and overarm

dust collection system. GuruGene designed, engineered and

fabricated the whole overarm system for a fraction of the cost of a

commercial product. The dust collector will attach at the top edge of

this PVC pipe system.

NEW tops to the radial arm saw work tables! In addition to the

new top surfaces, the tops have been extended out in the front and

end to allow for clamping anywhere along the edge.

Mobile Clamp Stand: A place for everything and everything in

its place! LOTS of NEW clamps (Bar clamps, spring clamps, c clamps,

Quick Grips, corner clamps, etc.) and a wonderful mobile stand which

allows the clamps to be moved to where the work is and FREES up LOTS

of space in the tool room. This guru designed stand now holds 113

clamps! He mentions to me that there IS a blank side left for MORE!

Note the box at the top for all of the various glues as well.

The new JET Air Filtration system. This unit has multiple filters and

removes particles from the air passing through up to 1 micron in

size. The filters can be blown off or washed. It changes the air in

the shop about 4 times an hour. It is operated from the shop floor by

means of a remote (shown in its holder on the rolling shop cart in

the picture to the right.) There are 3 fan speeds and it can be set

to delay turning off for 2,4 and 8 hours. So, we can finish up our

work and set the air cleaner to run for a selected period of time

after we have left. Notice the power cord reel to the right of the

air cleaner. We now have three of those reels installed on beams

allowing us to have drop down power for tools. We will, with the use

of these drop down power cords, minimize the number of cords crossing

the floor creating hazards.

Using tubes provided by our friend Ed Culbertson, we constructed a

rolling storage bin for cutoffs.

Gene has engineered a NEW table for the drill press (after making a previous new table top for this tool.) This one TILTS. Notice the clever use of the $1 aluminum framing triangle as an angle guage. You also should note the drill bit stand and the articulated dust collection nozzle. Because this old Craftsman drill press does not have a gear and crank system to raise and lower the table - Gene has cretaed a counterweight system using a bucket full of HEAVY chain!

Gene has redesigned and rebuilt the bin behind the radial arm saw to

allow for proper sawdust collection attachments.

(In the construction or planning stage: new storage (OUTSIDE) for lumber, new flat material storage, improvements to the rear of shop work table and storage bins, wall mounted storage cabinets, reorganization of tool room storage.)

Send Rhett E-Mail: rhett.bryson@furman.edu